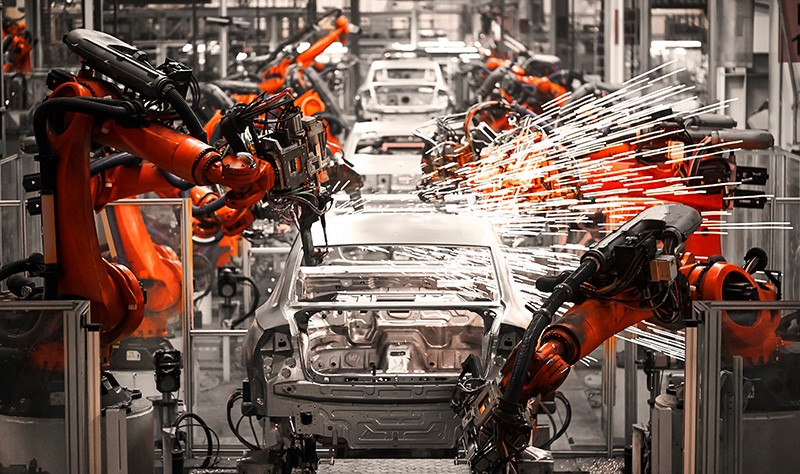

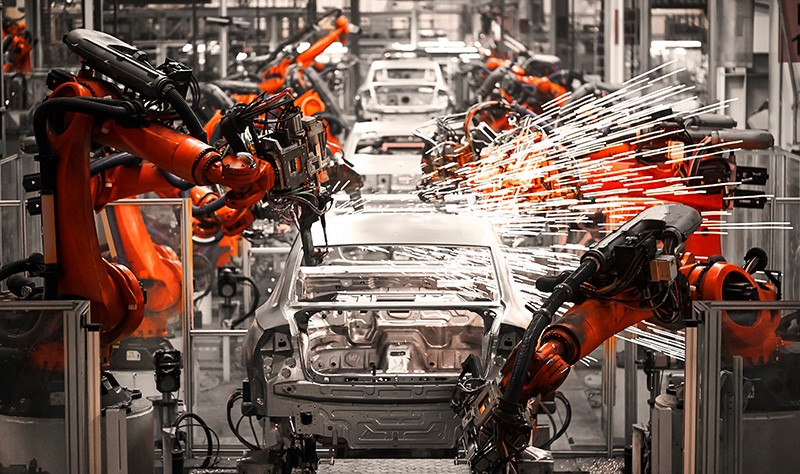

Enhancing manufacturing operations with automation

Enhancing manufacturing operations with automation

Automation streamlines critical manufacturing processes such as production scheduling, inventory management, and quality control, reducing manual effort and improving consistency. By automating routine tasks, manufacturers can accelerate production cycles, reduce errors, and optimize resource utilization, leading to improved product quality, lower costs, and greater operational efficiency.

Automation streamlines critical manufacturing processes such as production scheduling, inventory management, and quality control, reducing manual effort and improving consistency. By automating routine tasks, manufacturers can accelerate production cycles, reduce errors, and optimize resource utilization, leading to improved product quality, lower costs, and greater operational efficiency.

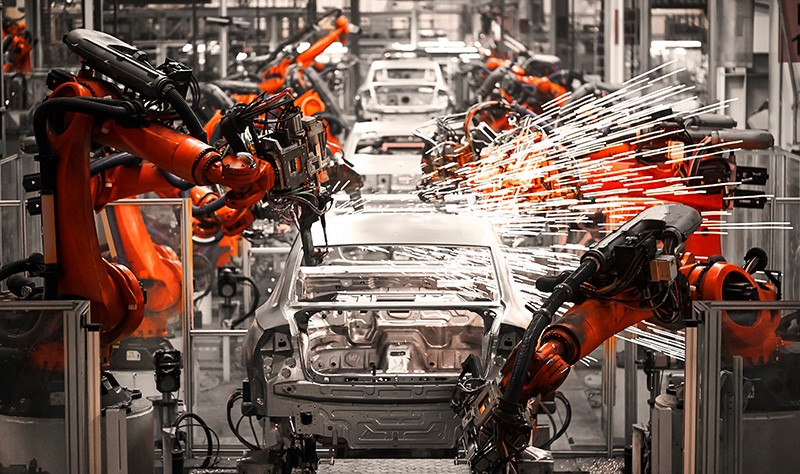

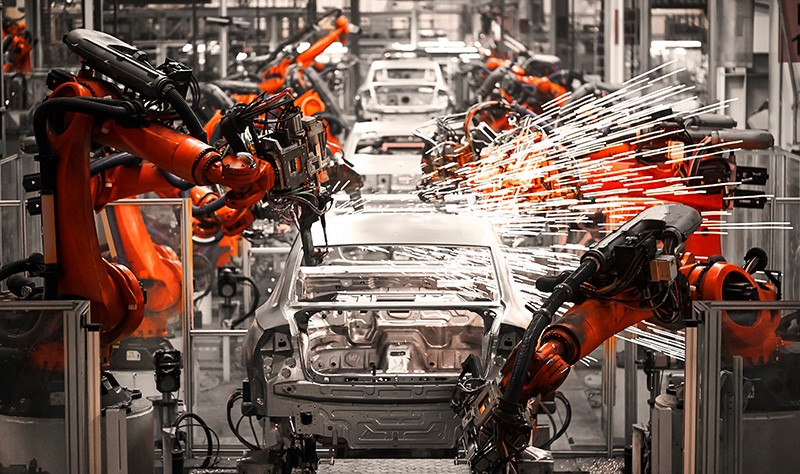

Optimizing manufacturing with automation

Production Efficiency

Automation optimizes production workflows, reducing manual labor and minimizing errors. It ensures faster production cycles, increases throughput, and maximizes the use of machinery, which results in higher efficiency and fewer delays.

Production Efficiency

Automation optimizes production workflows, reducing manual labor and minimizing errors. It ensures faster production cycles, increases throughput, and maximizes the use of machinery, which results in higher efficiency and fewer delays.

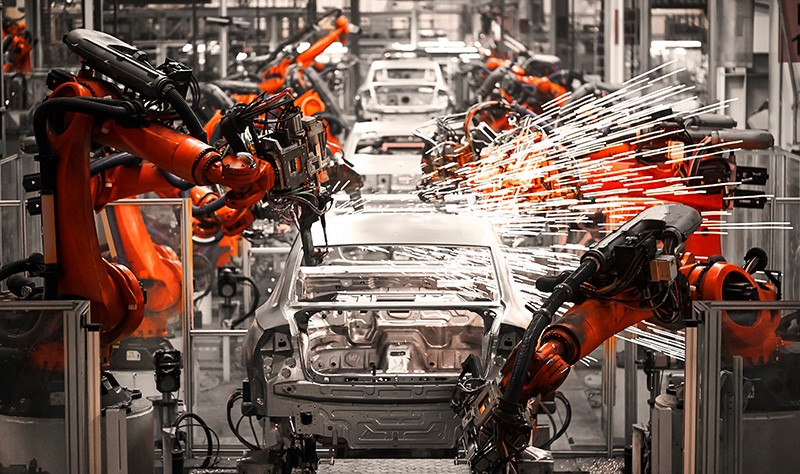

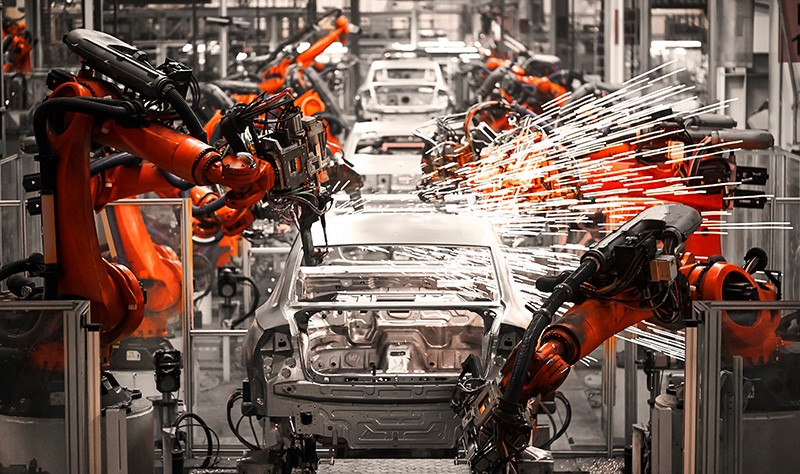

Quality Control

Automated systems monitor production lines in real-time, identifying defects and ensuring consistent product quality. With automation, manufacturers can maintain stringent quality standards, reduce rework, and prevent costly recalls.

Quality Control

Automated systems monitor production lines in real-time, identifying defects and ensuring consistent product quality. With automation, manufacturers can maintain stringent quality standards, reduce rework, and prevent costly recalls.

Quality Control

Automated systems monitor production lines in real-time, identifying defects and ensuring consistent product quality. With automation, manufacturers can maintain stringent quality standards, reduce rework, and prevent costly recalls.

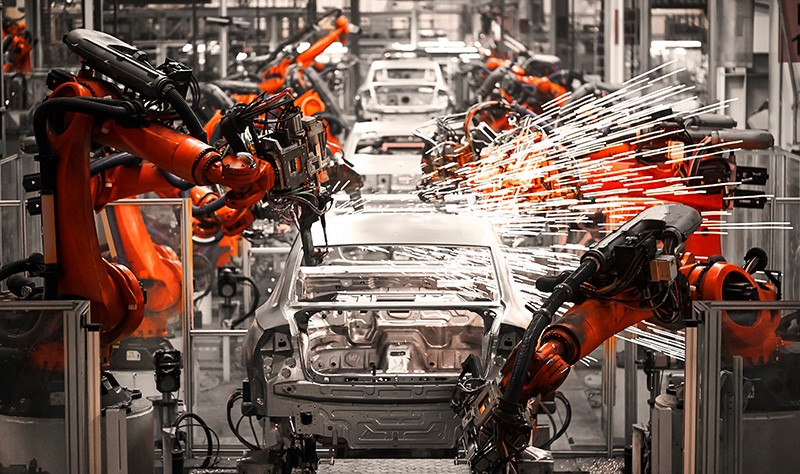

Operational Agility

Automation enhances the ability to quickly adapt to changes in demand or production schedules. By enabling flexible production lines and faster adjustments, manufacturers can respond more efficiently to market shifts and customer needs.

Operational Agility

Automation enhances the ability to quickly adapt to changes in demand or production schedules. By enabling flexible production lines and faster adjustments, manufacturers can respond more efficiently to market shifts and customer needs.

Operational Agility

Automation enhances the ability to quickly adapt to changes in demand or production schedules. By enabling flexible production lines and faster adjustments, manufacturers can respond more efficiently to market shifts and customer needs.

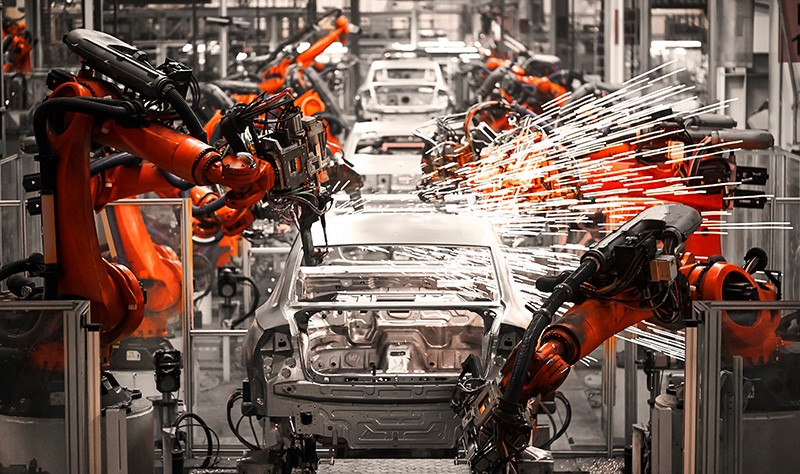

Automate your manufacturing industry

Production and Maintenance

After-Sale and Service Automation

Supply Chain and Management Automation

Sourcing and Purchasing Automation

Production and Maintenance

Automation in production and maintenance focuses on reducing downtime, enhancing productivity, and ensuring quality. By automating machine maintenance schedules, quality control, and production workflows, manufacturers can reduce errors and improve efficiency.

Business use cases:

Predictive Maintenance

Automated Production Scheduling

Quality Control Automation

Inventory Management

Production and Maintenance

After-Sale and Service Automation

Supply Chain and Management Automation

Sourcing and Purchasing Automation

Production and Maintenance

Automation in production and maintenance focuses on reducing downtime, enhancing productivity, and ensuring quality. By automating machine maintenance schedules, quality control, and production workflows, manufacturers can reduce errors and improve efficiency.

Business use cases:

Predictive Maintenance

Automated Production Scheduling

Quality Control Automation

Inventory Management

Production and Maintenance

Automation in production and maintenance focuses on reducing downtime, enhancing productivity, and ensuring quality. By automating machine maintenance schedules, quality control, and production workflows, manufacturers can reduce errors and improve efficiency.

Business use cases:

Predictive Maintenance

Automated Production Scheduling

Quality Control Automation

Inventory Management

After-Sale and Service Automation

In after-sales and service, automation improves customer support, reduces service time, and enhances customer satisfaction. By automating service requests, complaint handling, and warranty processes, companies can provide a better post-purchase experience.

Business use cases:

Service Request Automation

Warranty Claims

Customer Feedback Collection

Field Service Management

Supply Chain and Management Automation

Automation in supply chain and management enhances the efficiency of logistics, transportation, and order fulfillment. It ensures real-time tracking of goods, improves demand forecasting, and optimizes warehouse operations.

Business use cases:

Inventory Management

Logistics Automation

Demand Forecasting

Order Fulfillment Automation

Sourcing and Purchasing Automation

Automation in sourcing and purchasing optimizes supplier selection, order creation, and inventory management. It ensures timely procurement, reduces manual errors, and enhances decision-making by analyzing supplier performance and purchase data in real-time.

Business use cases:

Automated Supplier Selection

RFQ (Request for Quotation)

Purchase Order Creation

Supplier Risk Management

Production and Maintenance

Automation in production and maintenance focuses on reducing downtime, enhancing productivity, and ensuring quality. By automating machine maintenance schedules, quality control, and production workflows, manufacturers can reduce errors and improve efficiency.

Business use cases:

Predictive Maintenance

Automated Production Scheduling

Quality Control Automation

Inventory Management

After-Sale and Service Automation

In after-sales and service, automation improves customer support, reduces service time, and enhances customer satisfaction. By automating service requests, complaint handling, and warranty processes, companies can provide a better post-purchase experience.

Business use cases:

Service Request Automation

Warranty Claims

Customer Feedback Collection

Field Service Management

Supply Chain and Management Automation

Automation in supply chain and management enhances the efficiency of logistics, transportation, and order fulfillment. It ensures real-time tracking of goods, improves demand forecasting, and optimizes warehouse operations.

Business use cases:

Inventory Management

Logistics Automation

Demand Forecasting

Order Fulfillment Automation

Sourcing and Purchasing Automation

Automation in sourcing and purchasing optimizes supplier selection, order creation, and inventory management. It ensures timely procurement, reduces manual errors, and enhances decision-making by analyzing supplier performance and purchase data in real-time.

Business use cases:

Automated Supplier Selection

RFQ (Request for Quotation)

Purchase Order Creation

Supplier Risk Management

Production and Maintenance

Automation in production and maintenance focuses on reducing downtime, enhancing productivity, and ensuring quality. By automating machine maintenance schedules, quality control, and production workflows, manufacturers can reduce errors and improve efficiency.

Business use cases:

Predictive Maintenance

Automated Production Scheduling

Quality Control Automation

Inventory Management

After-Sale and Service Automation

In after-sales and service, automation improves customer support, reduces service time, and enhances customer satisfaction. By automating service requests, complaint handling, and warranty processes, companies can provide a better post-purchase experience.

Business use cases:

Service Request Automation

Warranty Claims

Customer Feedback Collection

Field Service Management

Supply Chain and Management Automation

Automation in supply chain and management enhances the efficiency of logistics, transportation, and order fulfillment. It ensures real-time tracking of goods, improves demand forecasting, and optimizes warehouse operations.

Business use cases:

Inventory Management

Logistics Automation

Demand Forecasting

Order Fulfillment Automation

Sourcing and Purchasing Automation

Automation in sourcing and purchasing optimizes supplier selection, order creation, and inventory management. It ensures timely procurement, reduces manual errors, and enhances decision-making by analyzing supplier performance and purchase data in real-time.

Business use cases:

Automated Supplier Selection

RFQ (Request for Quotation)

Purchase Order Creation

Supplier Risk Management

Production and Maintenance

Automation in production and maintenance focuses on reducing downtime, enhancing productivity, and ensuring quality. By automating machine maintenance schedules, quality control, and production workflows, manufacturers can reduce errors and improve efficiency.

Business use cases:

Predictive Maintenance

Automated Production Scheduling

Quality Control Automation

Inventory Management

After-Sale and Service Automation

In after-sales and service, automation improves customer support, reduces service time, and enhances customer satisfaction. By automating service requests, complaint handling, and warranty processes, companies can provide a better post-purchase experience.

Business use cases:

Service Request Automation

Warranty Claims

Customer Feedback Collection

Field Service Management

Supply Chain and Management Automation

Automation in supply chain and management enhances the efficiency of logistics, transportation, and order fulfillment. It ensures real-time tracking of goods, improves demand forecasting, and optimizes warehouse operations.

Business use cases:

Inventory Management

Logistics Automation

Demand Forecasting

Order Fulfillment Automation

Sourcing and Purchasing Automation

Automation in sourcing and purchasing optimizes supplier selection, order creation, and inventory management. It ensures timely procurement, reduces manual errors, and enhances decision-making by analyzing supplier performance and purchase data in real-time.

Business use cases:

Automated Supplier Selection

RFQ (Request for Quotation)

Purchase Order Creation

Supplier Risk Management

Discover how Flowifier fits every industry

Discover how Flowifier fits every industry

Explore how Flowifier optimized operations, leading to better outcomes in this case scenarios.

Production

Sourcing and Purchasing

Supply Chain Management

Production Scheduling

Automating production workflows helps schedule tasks, allocate resources, and track progress in real-time. It ensures the right materials, equipment, and personnel are available, reducing downtime and improving efficiency.

Production

Production Scheduling

Automating production workflows helps schedule tasks, allocate resources, and track progress in real-time. It ensures the right materials, equipment, and personnel are available, reducing downtime and improving efficiency.

Sourcing and Purchasing

Supplier Management

Streamlining the procurement process by automating supplier evaluation, order approvals, and inventory management. It ensures timely purchasing, reduces errors, and enhances communication with suppliers.

Supply Chain Management

Inventory and Order Management

Automating inventory tracking and order processing ensures stock levels are optimized and orders are fulfilled on time. It provides real-time updates to manage supply and demand efficiently.

Production

Production Scheduling

Automating production workflows helps schedule tasks, allocate resources, and track progress in real-time. It ensures the right materials, equipment, and personnel are available, reducing downtime and improving efficiency.

Sourcing and Purchasing

Supplier Management

Streamlining the procurement process by automating supplier evaluation, order approvals, and inventory management. It ensures timely purchasing, reduces errors, and enhances communication with suppliers.

Supply Chain Management

Inventory and Order Management

Automating inventory tracking and order processing ensures stock levels are optimized and orders are fulfilled on time. It provides real-time updates to manage supply and demand efficiently.

Production

Production Scheduling

Automating production workflows helps schedule tasks, allocate resources, and track progress in real-time. It ensures the right materials, equipment, and personnel are available, reducing downtime and improving efficiency.

Sourcing and Purchasing

Supplier Management

Streamlining the procurement process by automating supplier evaluation, order approvals, and inventory management. It ensures timely purchasing, reduces errors, and enhances communication with suppliers.

Supply Chain Management

Inventory and Order Management

Automating inventory tracking and order processing ensures stock levels are optimized and orders are fulfilled on time. It provides real-time updates to manage supply and demand efficiently.

Production

Production Scheduling

Automating production workflows helps schedule tasks, allocate resources, and track progress in real-time. It ensures the right materials, equipment, and personnel are available, reducing downtime and improving efficiency.

Sourcing and Purchasing

Supplier Management

Streamlining the procurement process by automating supplier evaluation, order approvals, and inventory management. It ensures timely purchasing, reduces errors, and enhances communication with suppliers.

Supply Chain Management

Inventory and Order Management

Automating inventory tracking and order processing ensures stock levels are optimized and orders are fulfilled on time. It provides real-time updates to manage supply and demand efficiently.

PRODUCTION

Production Scheduling

Automating production workflows helps schedule tasks, allocate resources, and track progress in real-time. It ensures the right materials, equipment, and personnel are available, reducing downtime and improving efficiency.

SOURCING AND PURCHASING

Supplier Management

Streamlining the procurement process by automating supplier evaluation, order approvals, and inventory management. It ensures timely purchasing, reduces errors, and enhances communication with suppliers.

SUPPLY CHAIN MANAGEMENT

Inventory and Order Management

Automating inventory tracking and order processing ensures stock levels are optimized and orders are fulfilled on time. It provides real-time updates to manage supply and demand efficiently.

PRODUCTION

Production Scheduling

Automating production workflows helps schedule tasks, allocate resources, and track progress in real-time. It ensures the right materials, equipment, and personnel are available, reducing downtime and improving efficiency.

SOURCING AND PURCHASING

Supplier Management

Streamlining the procurement process by automating supplier evaluation, order approvals, and inventory management. It ensures timely purchasing, reduces errors, and enhances communication with suppliers.

SUPPLY CHAIN MANAGEMENT

Inventory and Order Management

Automating inventory tracking and order processing ensures stock levels are optimized and orders are fulfilled on time. It provides real-time updates to manage supply and demand efficiently.

PRODUCTION

Production Scheduling

Automating production workflows helps schedule tasks, allocate resources, and track progress in real-time. It ensures the right materials, equipment, and personnel are available, reducing downtime and improving efficiency.

SOURCING AND PURCHASING

Supplier Management

Streamlining the procurement process by automating supplier evaluation, order approvals, and inventory management. It ensures timely purchasing, reduces errors, and enhances communication with suppliers.

SUPPLY CHAIN MANAGEMENT

Inventory and Order Management

Automating inventory tracking and order processing ensures stock levels are optimized and orders are fulfilled on time. It provides real-time updates to manage supply and demand efficiently.

PRODUCTION

Production Scheduling

Automating production workflows helps schedule tasks, allocate resources, and track progress in real-time. It ensures the right materials, equipment, and personnel are available, reducing downtime and improving efficiency.

SOURCING AND PURCHASING

Supplier Management

Streamlining the procurement process by automating supplier evaluation, order approvals, and inventory management. It ensures timely purchasing, reduces errors, and enhances communication with suppliers.

SUPPLY CHAIN MANAGEMENT

Inventory and Order Management

Automating inventory tracking and order processing ensures stock levels are optimized and orders are fulfilled on time. It provides real-time updates to manage supply and demand efficiently.

Manufacturing Resources

Manufacturing Resources

BLOG

How Automation is Supercharging Production Efficiency

Automation is transforming manufacturing by optimizing production schedules, material handling, and equipment monitoring. By automating these key processes, manufacturers reduce human error, increase output, and lower costs. Real-time adjustments and automated quality checks ensure smoother, faster production cycles.

Read it

BLOG

How Automation is Supercharging Production Efficiency

Automation is transforming manufacturing by optimizing production schedules, material handling, and equipment monitoring. By automating these key processes, manufacturers reduce human error, increase output, and lower costs. Real-time adjustments and automated quality checks ensure smoother, faster production cycles.

Read it

BLOG

How Automation is Supercharging Production Efficiency

Automation is transforming manufacturing by optimizing production schedules, material handling, and equipment monitoring. By automating these key processes, manufacturers reduce human error, increase output, and lower costs. Real-time adjustments and automated quality checks ensure smoother, faster production cycles.

Read it

BLOG

Why Predictive Maintenance is a Game-Changer for Manufacturers

Predictive maintenance is taking the guesswork out of equipment upkeep. With automated monitoring and predictive analytics, manufacturers can foresee potential issues and perform maintenance only when necessary, reducing downtime and extending equipment lifespans. This approach leads to higher uptime and more efficient operations.

Read it

BLOG

Why Predictive Maintenance is a Game-Changer for Manufacturers

Predictive maintenance is taking the guesswork out of equipment upkeep. With automated monitoring and predictive analytics, manufacturers can foresee potential issues and perform maintenance only when necessary, reducing downtime and extending equipment lifespans. This approach leads to higher uptime and more efficient operations.

Read it

BLOG

Why Predictive Maintenance is a Game-Changer for Manufacturers

Predictive maintenance is taking the guesswork out of equipment upkeep. With automated monitoring and predictive analytics, manufacturers can foresee potential issues and perform maintenance only when necessary, reducing downtime and extending equipment lifespans. This approach leads to higher uptime and more efficient operations.

Read it

BLOG

The Power of Automation in Supply Chain Management

Automation is streamlining supply chains by automating tasks like inventory management, procurement, and order processing. With real-time tracking and automated reordering systems, manufacturers can avoid stockouts, reduce surplus inventory, and improve order fulfillment speed, driving greater efficiency and customer satisfaction.

Read it

BLOG

The Power of Automation in Supply Chain Management

Automation is streamlining supply chains by automating tasks like inventory management, procurement, and order processing. With real-time tracking and automated reordering systems, manufacturers can avoid stockouts, reduce surplus inventory, and improve order fulfillment speed, driving greater efficiency and customer satisfaction.

Read it

BLOG

The Power of Automation in Supply Chain Management

Automation is streamlining supply chains by automating tasks like inventory management, procurement, and order processing. With real-time tracking and automated reordering systems, manufacturers can avoid stockouts, reduce surplus inventory, and improve order fulfillment speed, driving greater efficiency and customer satisfaction.

Read it