Supply chains today are under immense pressure—from global disruptions to rising customer expectations. The key to staying competitive? Automation. By streamlining workflows, reducing inefficiencies, and enabling real-time visibility, automation is transforming supply chains from reactive systems into strategic powerhouses.

How Automation Is Driving Supply Chain Efficiency

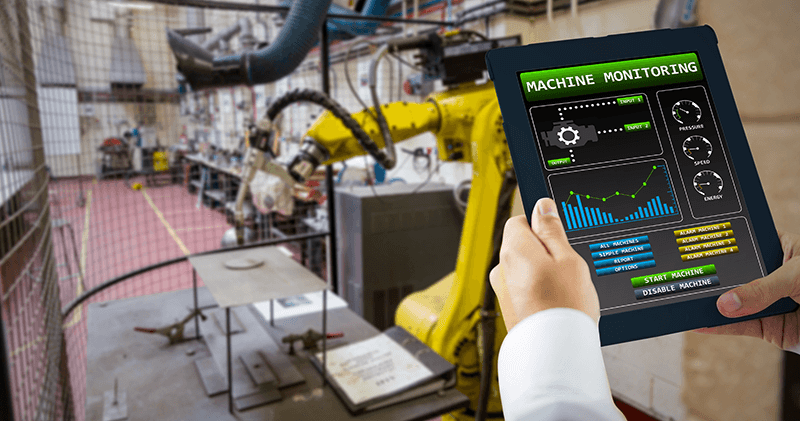

1. Enhanced Visibility and Decision-Making

Automation tools allow businesses to track inventory, shipments, and supplier activities in real-time. This transparency empowers organizations to anticipate disruptions and adjust operations proactively.

Real-Life Example: During the COVID-19 pandemic, a leading automotive manufacturer implemented automation for supply chain monitoring. This allowed them to quickly identify and mitigate delays, reducing downtime and meeting production schedules despite global shortages.

2. Streamlined Procurement Processes

Gone are the days of manual purchase orders and approval delays. Automation speeds up procurement cycles by automating repetitive tasks like supplier communication, purchase order creation, and approval workflows.

Real-Life Example: A consumer goods company optimized its procurement process by automating supplier quote evaluations and order approvals. As a result, their order cycle time was cut by 40%, ensuring materials arrived on time for production.

3. Accurate Inventory Management

Managing inventory levels manually often leads to overstocking or stockouts. Automation ensures accurate tracking and triggers replenishments based on real-time demand.

Real-Life Example: A global retailer used automation to analyze purchasing patterns and predict seasonal demand spikes. By dynamically adjusting inventory, they avoided overstocking, reduced carrying costs, and improved profitability.

4. Faster and Error-Free Order Fulfillment

From order validation to shipping, automation ensures accuracy and speed at every step of order fulfillment.

Real-Life Example: An electronics distributor automated its order matching and shipping processes, increasing accuracy by 30% and reducing delivery times by two days on average.

5. Compliance and Documentation Made Easy

Trade compliance, tax regulations, and environmental standards can be overwhelming to manage manually. Automation ensures that every transaction is compliant, reducing risks and audit-related stress.

Real-Life Example: A logistics company handling cross-border shipments integrated automation to manage customs compliance. The result? Clearance times were cut by 50%, and errors in documentation were virtually eliminated.

Key Benefits of Automation for Supply Chains

When applied effectively, automation delivers transformative benefits:

Faster Operations: Reduces delays across procurement, production, and shipping.

Improved Accuracy: Eliminates human errors in data entry, inventory tracking, and order processing.

Cost Efficiency: Optimizes resource use and minimizes waste.

Resilience: Enables rapid adaptation to market changes or unexpected disruptions.

Customer Satisfaction: Ensures timely deliveries and enhances service levels.

Real-Life Success Stories in Supply Chain Automation

Walmart: Optimizing Inventory

Walmart uses automation to track millions of SKUs across its global operations. By analyzing sales trends and inventory data in real-time, Walmart ensures shelves are stocked with high-demand products while minimizing overstock. This system has significantly improved their operational efficiency and customer satisfaction.

Amazon: Speeding Up Order Fulfillment

Amazon’s supply chain is synonymous with speed. Automation enables seamless integration of inventory systems, robots in fulfillment centers, and real-time order tracking. This has helped Amazon offer two-day and even same-day shipping, setting a new industry benchmark.

Unilever: Sustainability and Efficiency

Unilever automated its supply chain to reduce its environmental impact. By optimizing routes and production schedules, they achieved a 15% reduction in carbon emissions while lowering logistics costs.

How to Get Started with Automation in Your Supply Chain

Embarking on automation doesn’t require a complete overhaul. Here’s how to start:

Identify Bottlenecks: Analyze your current supply chain to pinpoint inefficiencies.

Set Clear Goals: Focus on specific areas like inventory, procurement, or shipping for measurable results.

Pilot Small: Test automation in one segment before scaling across your supply chain.

Integrate Systems: Ensure that all departments and tools are connected for smooth data flow.

Conclusion: The Future of Supply Chains

Automation is no longer a luxury; it’s a necessity for supply chain excellence. From predictive insights to error-free execution, automation empowers businesses to operate smarter, faster, and more sustainably.

For organizations ready to embrace the future, automation offers the tools to stay ahead in an increasingly competitive and unpredictable world.