In today’s fast-paced manufacturing world, automation is the key to unlocking unprecedented levels of production efficiency. From reducing operational costs to improving quality and speeding up workflows, automation is transforming how companies manufacture products. We’ll explore how automation enhances production efficiency and how businesses can leverage these tools to stay ahead in a highly competitive market.

1. Streamlining Processes and Reducing Manual Labor

Automating repetitive tasks is one of the most impactful ways automation increases production efficiency. Machines, robots, and AI-powered systems can handle mundane and repetitive tasks such as assembly, packaging, or even data entry, which were traditionally done by humans. This not only reduces the chances of human error but also speeds up production processes. With fewer hands-on tasks for employees, labor costs decrease, and workers can focus on more value-added tasks.

For instance, companies like Tesla have integrated robotic systems in their assembly lines to handle tasks like welding and painting, reducing human errors while also increasing the pace of production.

2. Increasing Speed and Consistency in Production

Automation tools can work 24/7 without the need for breaks or downtime. By maintaining consistency in production cycles, automation ensures that the manufacturing process runs at optimal efficiency, delivering products faster and at higher quality. The ability to maintain a constant speed and precision without fatigue has allowed companies to meet demanding production targets and satisfy market needs on time.

A great example of this can be seen in Boeing, where automated tools are used to drill thousands of holes in airplane parts with high precision. These tools significantly increase the speed of production while also ensuring that quality standards are met.

3. Enhancing Supply Chain Efficiency

Automation extends beyond the factory floor and into supply chain management, an area that directly influences production efficiency. By utilizing predictive analytics and automated inventory management systems, companies can optimize stock levels, reduce excess inventory, and avoid stockouts. With accurate demand forecasting, production lines can be continuously fed with the necessary materials, preventing delays and improving overall workflow efficiency.

A prime example of automation enhancing supply chain efficiency is Amazon’s use of robotics in its fulfillment centers. Amazon uses automated guided vehicles (AGVs) and robotic arms to move and sort products, ensuring inventory is readily available for quick processing and shipment, reducing bottlenecks in the supply chain.

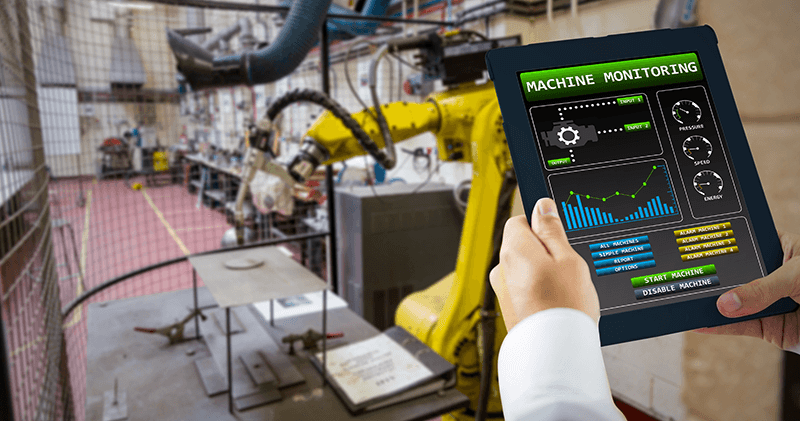

4. Optimizing Maintenance and Reducing Downtime

Automated systems also contribute to reducing downtime by predicting and preventing machine failures. With predictive maintenance tools, machines are monitored in real-time, and any signs of malfunction are detected before they result in costly breakdowns. Automated systems alert technicians, who can take action to repair the machines proactively, keeping production lines running smoothly without unexpected interruptions.

For example, General Electric (GE) uses IoT-enabled sensors and data analytics to monitor their machines in real-time. These sensors help detect issues such as overheating or vibrations, prompting repairs before a full breakdown occurs, thus reducing costly downtime and keeping production efficient.

5. Data-Driven Decision-Making for Continuous Improvement

The role of data in modern production cannot be overstated. Automation systems collect vast amounts of real-time data during the manufacturing process, providing manufacturers with actionable insights. This data allows businesses to analyze performance trends, identify inefficiencies, and pinpoint areas for improvement. With real-time feedback, managers can make data-driven decisions that continuously optimize production processes.

Companies like Siemens use data analytics tools integrated with their automated systems to track production efficiency across their entire manufacturing network. By analyzing production data, they can adjust processes in real-time, optimizing workflows and increasing overall productivity.

6. Reducing Waste and Improving Sustainability

Automation doesn’t just enhance efficiency; it also plays a role in reducing waste and improving sustainability. With automated systems in place, companies can more accurately measure resources, ensuring minimal waste in raw materials. Moreover, automation can help manufacturers recycle materials and optimize energy use, leading to a smaller environmental footprint.

For example, Unilever has implemented automation technologies in its production lines that reduce water consumption, optimize energy use, and recycle waste. These measures help Unilever reduce its environmental impact while still meeting production demands.

Case Study: How BMW is Using Automation to Supercharge Efficiency

BMW is an excellent example of how automation can significantly impact production efficiency. The company has implemented advanced robotic systems and automated assembly lines in its factories to enhance vehicle production. Automated systems handle tasks like welding, part installation, and even painting, reducing the need for human intervention in repetitive tasks. This has allowed BMW to ramp up production while maintaining high-quality standards, decreasing the time it takes to produce a vehicle, and enhancing overall productivity.

The Future of Automation in Production Efficiency

The future of automation in manufacturing is filled with exciting possibilities. With the advancement of artificial intelligence, machine learning, and the Internet of Things (IoT), automation will continue to evolve. These technologies will bring even smarter solutions to optimize production efficiency, predict trends, and further reduce costs. The integration of AI into automation systems will allow manufacturers to anticipate customer demands, streamline supply chains, and deliver highly customized products faster than ever.

Conclusion

Automation is no longer a luxury—it’s a necessity for staying competitive in the manufacturing sector. By embracing automation technologies, companies can streamline their operations, improve efficiency, reduce waste, and drive sustainability efforts. From reducing downtime with predictive maintenance to enhancing supply chain management with automated systems, automation is transforming how businesses operate. As the technology continues to evolve, the future of production is automated, faster, and more efficient than ever before.