In today’s fast-paced, ever-evolving high-tech industry, supply chain efficiency is more important than ever. The rise of global markets, rapid product lifecycles, and increasing customer demands are driving businesses to rethink traditional supply chain models. The secret to a smarter, more efficient high-tech supply chain lies in automation and data-driven insights.

How automation and emerging technologies are transforming supply chains in high-tech industries, making them more agile, transparent, and cost-effective. With the integration of smart solutions, high-tech companies can not only streamline operations but also gain a competitive edge in an increasingly complex market.

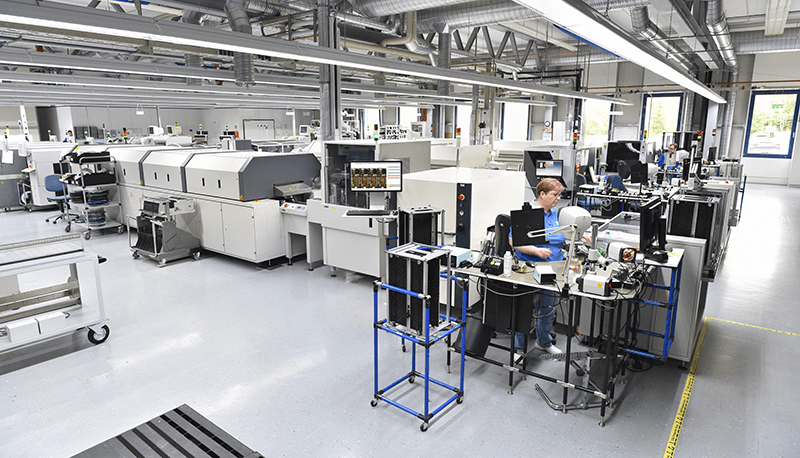

1. Automation: The Backbone of a Smarter Supply Chain

Automation in supply chain management isn’t just about replacing manual tasks with machines—it’s about creating a seamless flow of operations that are faster, more accurate, and less prone to human error. In high-tech industries, where precision and speed are critical, automation is the key to improving inventory management, order fulfillment, and demand forecasting.For instance, automating order processing allows companies to track real-time inventory levels, instantly updating stock across systems. This reduces errors in stock levels, minimizes the risk of overstocking or stockouts, and enhances order accuracy.

Case Study: A major electronics manufacturer integrated automated systems to monitor their inventory and logistics, resulting in a 30% reduction in operational costs and faster turnaround times. By automating repetitive tasks, they freed up resources to focus on more strategic activities, such as supplier relationship management and innovation.

2. Data-Driven Decision Making

In high-tech industries, the pace of innovation and the need for precision requires supply chain managers to make decisions based on real-time data. Data-driven supply chains are smarter because they allow for predictive insights, which can optimize procurement, distribution, and logistics.Advanced technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) provide real-time monitoring of production processes, supply chain conditions, and consumer demand. By leveraging this data, businesses can predict disruptions, forecast demand more accurately, and ensure that supply chain resources are allocated efficiently.

Example: A leading tech giant adopted AI-driven predictive analytics to forecast component demand and align their production schedules accordingly. This move helped them avoid costly delays and ensure that they had the right materials at the right time.

3. Blockchain: Enhancing Transparency and Security

Transparency is crucial for high-tech supply chains, especially when dealing with sensitive data, intellectual property, and global suppliers. Blockchain technology is revolutionizing the way companies track and verify transactions across the supply chain.With blockchain, every transaction—from supplier to manufacturer to customer—is securely recorded, creating an immutable audit trail. This not only enhances transparency but also reduces the risk of fraud, ensuring that products are genuine and that supply chain partners are held accountable.

Real-World Example: A global smartphone manufacturer implemented blockchain to track the provenance of components in their supply chain. This innovation improved product authenticity, ensured regulatory compliance, and allowed customers to verify the quality of materials used in their products.

4. Cloud-Based Collaboration for Seamless Integration

In high-tech industries, supply chains often span across multiple countries and involve many different suppliers, manufacturers, and distributors. This complexity makes collaboration between partners more challenging, especially when using outdated systems. Cloud-based supply chain management systems are changing the game by enabling real-time collaboration and data sharing between all stakeholders.These platforms allow supply chain partners to have a single source of truth, ensuring that all parties are on the same page regarding inventory, production schedules, and delivery expectations. Cloud-based tools can integrate with ERP (Enterprise Resource Planning) and CRM (Customer Relationship Management) systems to streamline processes from order management to customer delivery.

Case Study: A semiconductor company transitioned to a cloud-based supply chain management system, which allowed them to better coordinate with their suppliers in Asia and improve on-time delivery rates by 40%. The platform also improved inventory visibility, helping the company reduce stockouts and manage costs more effectively.

5. Sustainability and the Smart Supply Chain

Sustainability has become a key consideration for high-tech companies. With growing consumer awareness and stricter environmental regulations, it’s no surprise that businesses are looking for ways to make their supply chains more sustainable. A smarter supply chain doesn’t just focus on speed and cost—it also considers the environmental and social impact of operations.Automation, AI, and data analytics can help companies reduce waste, optimize energy use, and improve the sustainability of their operations. For example, companies can use data to identify inefficiencies in the supply chain that lead to excess waste or unnecessary emissions, and then apply targeted solutions to mitigate those issues.

Example: A global tech company revamped its supply chain with sustainability in mind by implementing smart energy management systems and automated route optimization for its delivery vehicles. This reduced energy consumption by 15%, cutting both costs and carbon emissions.

6. The Future of High-Tech Supply Chains

As automation and data analytics continue to evolve, so too will the high-tech supply chain. The next frontier lies in the integration of AI, robotics, and predictive analytics to create fully autonomous supply chains. These systems will be able to make decisions in real time, further minimizing delays, costs, and inefficiencies.With advancements in machine learning and robotics, warehouses and distribution centers will become increasingly automated, allowing for faster, more accurate order fulfillment. Predictive analytics will enable companies to respond instantly to changing market conditions, consumer demands, and supply chain disruptions.

What’s Next: The next generation of high-tech supply chains will be entirely connected, with AI systems continuously learning from data and evolving to become more efficient over time. The combination of automation, data intelligence, and cutting-edge technologies will redefine what’s possible in supply chain management.

Conclusion

The secret to a smarter high-tech supply chain lies in embracing automation and technology to optimize processes, enhance transparency, and increase efficiency. By adopting these advanced tools, companies can stay ahead of the competition, reduce costs, and deliver products faster and more reliably.If your business is looking to unlock the full potential of your supply chain, now is the time to embrace automation and data-driven solutions. The future of high-tech operations is smarter, faster, and more connected than ever before.